Hello citizen! Here you can find all the files and information you need to build your favourite OpenBike model.

This is not about bicycles!

Open your eyes, this is about you, about your attitude towards the future. Do you think that the pollution of the cities will disappear by itself? Do you think traffic jams are caused by others? Do you know how much free space a car occupies? Do you know the technologies available in your own city? How much energy is used to fabricate or repair a car, and a bicycle? What if instead of materials, we transported data? These, among others, are the questions we asked ourselves when we decided to create OpenBike.

If you think you can improve your environment, if you think you can contribute something positive to your city, if you believe in an active and nonconformist society, we would like to see how you get involved. We believe that the big changes start with you, so download, make, modify and share.

RIDE FREE!

How to build your bike:

1. Download

Choose your favorite OpenBike and download the manufacturing files.

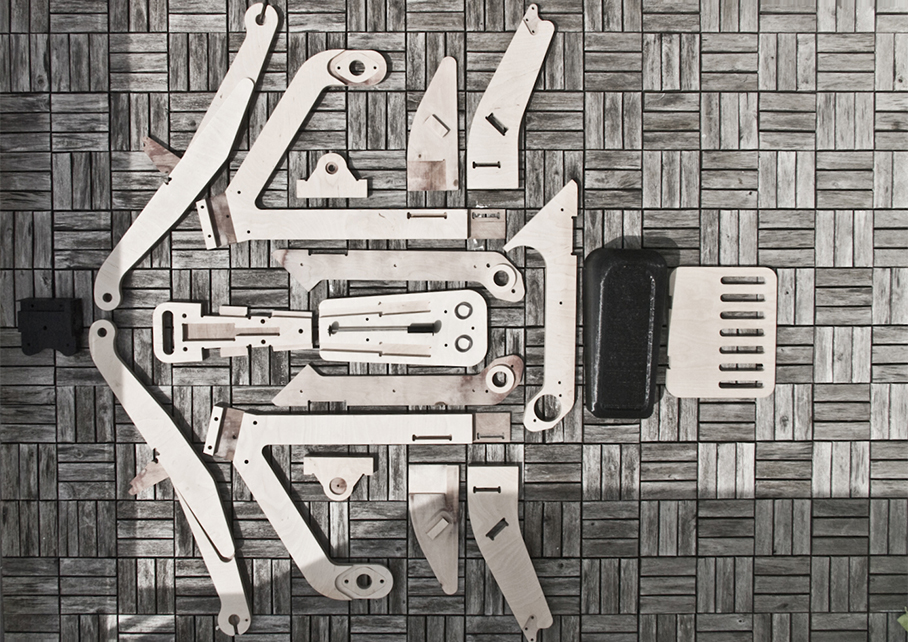

These are the digital files you need to build the parts that make up your bike.

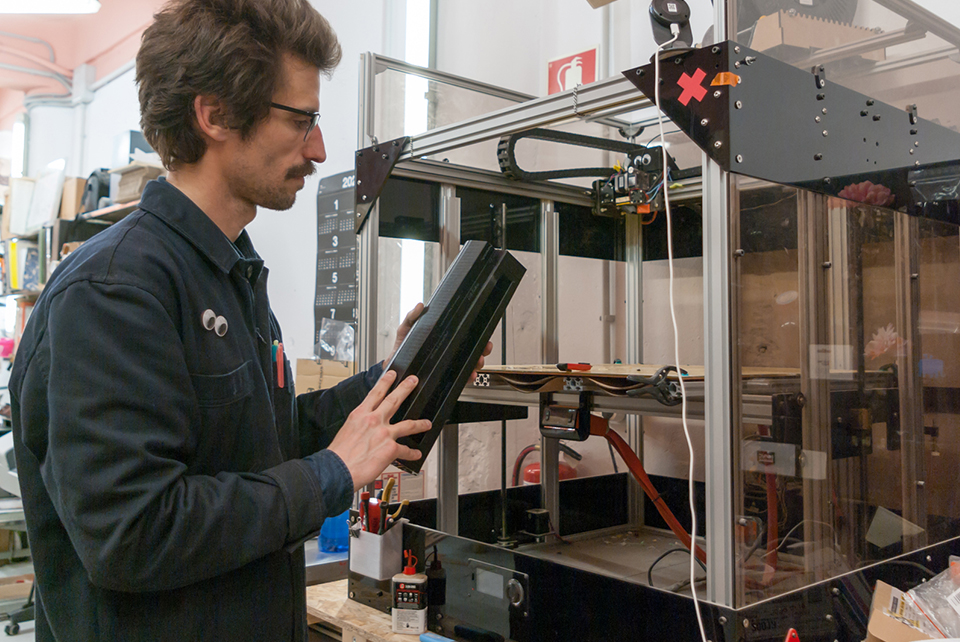

There are two types of files: those that should be manufactured with a CNC milling machine and those that need to be manufactured with a 3D PRINTER.

2. Customise

Adapt our OpenBike designs to your personal needs and preferences.

Whether it’s a rear rack to carry your groceries or an extra seat to bring your kids with you, you are more than welcome to introduce any changes to our designs. Feel free to share your modifications with us so that we can learn from each other : )

3. Build

Find a local manufacturer.

We encourage you to find local dealers with access to a CNC milling machine and a 3D printer in order to manufacture the parts required to build your bike.

Once these parts are ready, just follow the manuals provided for each bike in order to assemble it.

4. Share

Every bike counts.

We understand our community as a chance to share knowledge, modify and improve our designs.

If you decide to build one of our bikes, please let us know how the process was. We are more than willing to learn from the ups and downs.

Every feedback matters, so feel free to share your experience with us!

Choose your bike:

Rev4

An improvement on the OpenBike Rev 3 model.

It incorporates front and rear grills so that you can use it to transport goods.

Its fork design allows wider turns and the new saddle design makes it more comfortable and easy to print. The handlebar bar is removable.

- Birch plywood 21 mm

- 5 mm aluminum plate

- TPU filament (for 3D printer)

- Carbon Fiber PLA Filament (for 3D printer)

- Carpenter white glue

- CNC milling machine

- 3D printer

- Mace

- Allen wrenches

- BB86 press fit bottom bracket

- Single speed crankset 24 mm spindle (50t)

- Chain

- Flat pedals

- 1 1/8” Stem lock 200-225 mm

- Tapered 1 1/8” headset

- 20” rear wheel with coaster brake 9’5 x 110mm

- 20” front wheel 9’5 x 110mm

- 18t sprocket

- Screws

Rev3

In the OpenBike Rev 3, we used everything we learned from the OpenBike Rev 2 to develop a new, more universal design.

We changed the design of the frame to get a smaller bike that can be used by people of different heights, going from 26″ wheels to 20″ wheels.

We designed a saddle made by 3D printing with flexible plastic, thus increasing the number of parts fabricated by ourselves.

- Birch plywood 21 mm

- 5 mm aluminum plate

- TPU filament (for 3D printer)

- Carbon Fiber PLA Filament (for 3D printer)

- Carpenter white glue

- CNC milling machine

- 3D printer

- Mace

- Allen wrenches

- BB86 press fit bottom bracket

- Single speed crankset 24mm spindle (50t)

- Chain

- Flat pedals

- 1 1/8” stem lock 200-225 mm

- Tapered 1 1/8” headset

- 20” rear wheel with coaster brake 9’5 x 110 mm

- 20” front wheel 9’5 x 110mm

- 18t sprocket

- Screws

Rev2

The design is based on the OpenBike Rev 1 model.

We increased the weight of the frame and fork in order to make the bike more stable.

We also added a front grill that allows you to transport small loads and a rear piece to house a LED light that can be controlled from your phone (have a look here).

- Birch plywood 21 mm

- 5 mm aluminum plate

- Carbon Fiber PLA Filament (for 3D printer)

- Carpenter white glue

- Adafruit Feather nRF52 Bluefruit

- CNC milling machine

- 3D printer

- Mace

- Allen wrenches

- BB86 press fit bottom bracket

- Single speed crankset 24 mm spindle (50t)

- Chain

- Flat pedals

- Stem lock MISUMI parts N. SCLBRM20-200, CBSST12-35, NLDF12

- Headset bearings MISUMI part N. BA2035

- 20” rear wheel with coaster brake 9’5 x 110 mm

- 20” front wheel 9’5 x 110mm

- 18t sprocket

- Saddle

- Screws

Rev1

This is our first OpenBike model.

For three months, we worked on this design with a group of people in the citizen laboratory of Tabakalera (San Sebastián).

It is a functional bike model but it lacks stability.

- Birch plywood 21 mm

- 5 mm aluminum plate

- Carbon Fiber PLA Filament (for 3D printer)

- Carpenter white glue

- CNC milling machine

- 3D printer

- Mace

- Allen wrenches

- BB86 press fit bottom bracket

- Single speed crankset 24mm spindle (50t)

- Chain

- Flat pedals

- Stem lock threaded rod 12mm diam

- Headset bearings MISUMI part N. BA2035

- 20” rear wheel with coaster brake 9’5 x 110 mm

- 20” front wheel 9’5 x 110 mm

- 18t sprocket

- Saddle

- Screws